Learn how to select the proper equipment for your heat processing requirements.

Whether it is time to replace an existing industrial batch oven, upgrade a process with a new oven or set up an entirely new process that requires an industrial batch oven, there are numerous questions that may arise about how to put together the justification for a capital expenditure.

Whether it is time to replace an existing industrial batch oven, upgrade a process with a new oven or set up an entirely new process that requires an industrial batch oven, there are numerous questions that may arise about how to put together the justification for a capital expenditure.

If you’re at a loss as to where to start, or if you just want a framework to follow, this article will help identify the criteria to consider.

Starting the Search

Some of the basic questions revolve around the oven size, operating temperature, fuel source, available utilities, airflow pattern, instrumentation and lead time. As a general rule, these are the first questions asked and answered, but they are only the beginning of a critical exchange of information between you and the vendor. Ultimately, it is the communication between you and your vendor that will lead to the proper selection of equipment for your process needs.

Some of the basic questions revolve around the oven size, operating temperature, fuel source, available utilities, airflow pattern, instrumentation and lead time. As a general rule, these are the first questions asked and answered, but they are only the beginning of a critical exchange of information between you and the vendor. Ultimately, it is the communication between you and your vendor that will lead to the proper selection of equipment for your process needs.

Oven Size. Oven size is always a fascinating subject as it pertains to the process. Some feel the oven should be large enough to handle future business opportunities, and others want just enough space to handle current requirements. Usually, the project budget helps dictate how far you can go with size.

Overall though, the size should be related directly to the process needs. Future business is an unknown, and investing in an unknown future revenue stream is risky. Discuss your needs with the oven supplier to arrive at a size that will do the job. When selecting the oven size, remember to discuss any building restrictions that may pose an issue. Building doorways and ceiling heights are the most common issues that can affect how the oven is designed.

Operating Temperature. The required operating temperature has an effect on oven construction. There is a common belief that if you need a 475°F (246°C) operating temperature, then you should purchase a 650°F (343°C) unit. There are pros and cons to this theory. Discussing your particular need with your oven vendor will result in a selection that will meet your processing requirements. As a general rule, the higher the temperature, the higher the cost.

Fuel Source. The fuel source for the oven can be electricity, natural gas, propane or steam. The first three are the most common. Typically, oven size guides the fuel source selection. Large ovens are cost effective on natural gas or propane often are the most cost effective for large ovens while electricity is more cost effective for smaller or low temperature ovens. In some processes, only electricity can be used. Have your oven supplier discuss the fuel source differences and the relative operating costs for your area to determine a cost-effective solution.

Utilities. Equally important are the available utilities at your plant. Voltage and phase are required whether you are buying a gas oven or an electric oven. Knowing which utilities are available can help determine if you have the proper utilities in place to operate the equipment. The lack of utilities may add to your cost justification if a new gas line or electrical service is required but not identified up front.

Utilities. Equally important are the available utilities at your plant. Voltage and phase are required whether you are buying a gas oven or an electric oven. Knowing which utilities are available can help determine if you have the proper utilities in place to operate the equipment. The lack of utilities may add to your cost justification if a new gas line or electrical service is required but not identified up front.

Airflow. The airflow pattern inside the oven can make your life easy or difficult. Selecting from combination, compound horizontal, straight horizontal, vertical up or vertical down is truly determined by how you load the oven, taking into consideration the parts’ shape and size. For example, it would be a mistake to load a large stator into a straight horizontal oven, where one leading edge of hot air enters the chamber on the right and returns on the left. The hot air will transfer the energy to the right side of the part first, curing it faster than the left side. The proper selection for this example would be combination or compound horizontal with two leading edges of hot air entering the chamber from the left and right side and returning through the top or rear of the oven. Take airflow into consideration and discuss it with your sales engineer.

Instrumentation. Instrumentation is an important topic when selecting a control package for the oven. Controllers range from single setpoint to profiling, and they can be packaged with a recording option or stand alone. Recording devices come in paper or paperless, with many options. The right choices can only be made by using the correct information about the process you are performing. Take time to select the control package that will get the job done and again, discuss the options with your sales engineer.

Lead time only can be established once the oven is selected completely and workload schedules for the supplier can be reviewed. This is a variable that is constantly changing. The one thing that I have learned over the years is that everyone wants it faster than it can be built.

Specific Process Requirements

Now that you have your size, temperature, fuel source and other basic needs selected, it is time to gather additional information pertaining to your specific process needs.

Now that you have your size, temperature, fuel source and other basic needs selected, it is time to gather additional information pertaining to your specific process needs.

Paint curing, solvent venting, inert gas processing, composite curing, drying, aging and annealing are a short list of some of these specific processes. Some examples will be used to help you understand the requirements that are crucial to selecting the right oven for your application.

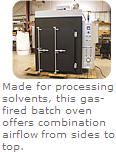

For instance, solvent venting is a common process requirement for industrial ovens whether you are curing solvent-based paints or varnishes. If your process requires solvent venting, be sure to specify the processing temperature and the amount and type of solvent being processed.

The construction of a solvent-venting unit may require pressure-relief panels and an exhaust blower. The unit also will have a purge cycle before allowing the heating circuit to energize. Once you have a material data safety sheet (MSDS) for the material you are processing in the oven, and you know the quantity of material being processed per batch, then the oven engineer can help guide you to the proper selection of a solvent-venting oven.

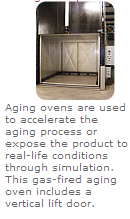

Aging is another common process requirement for ovens. Uniformity and instrumentation are two critical details for these types of units as aging ovens are used to accelerate the aging process or expose the product to real-life conditions through simulation. The process requires the product to get to the target temperature and hold it there uniformly for a specific period of time. Understanding the product loading is important so the work space and airflow pattern are designed to achieve the time to temperature and uniform part temperature specifications required. In some cases, live load testing of the products is required vs. an empty chamber survey. The oven engineer can help select the right equipment and options.