Donington Park is home to a museum containing many famous classic racing vehicles, including McLaren and Ferrari Formula 1 cars driven by the likes of Ayrton Senna and Michael Schumacher. Many of the vehicles in the museum are still used by enthusiasts, and the wear and tear inevitably takes its toll, but spares are hard to find.

Donington Park is home to a museum containing many famous classic racing vehicles, including McLaren and Ferrari Formula 1 cars driven by the likes of Ayrton Senna and Michael Schumacher. Many of the vehicles in the museum are still used by enthusiasts, and the wear and tear inevitably takes its toll, but spares are hard to find.

"Many spares are non-standard, high-specification products made in small number specifically for a vehicle and once that vehicle is no longer in production – effectively every year in the case of Formula 1 or touring cars – they are virtually impossible to track down," explains Kevin Wheatcroft, Donington Park's owner.

"We have worked out that the only way to do this is to create a highly detailed CAD image of the spare, and then supply this to a specialist manufacturer to produce the part to the correct size and specification for us."

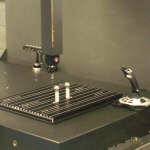

Image: Obtaining CAD surface data to support the manufacture of spares for famous F1 cars

What the team at Donington Grand Prix Collection have found to be most effective is white light scanning (supplied by Phase Vision, 01509 223632),where a 'structured image', typically containing the equivalent of hundreds or thousands of lines , is projected. By projecting a series of these images, the shape of the object can be calculated using triangulation – just like a laser scanner, but perhaps 10 or 100 times faster. Such a scanner can measure an area of metres in seconds and, because the scanned areas are enormous, the need to align scan patches is greatly reduced.

"We have found that using white light scanning is far quicker and able to deliver a more accurate representation of the part we are wishing to source. And the fact that we are able to supply such a faithful representation reduces the risk of errors in the reverse engineering process," emphasises Mr Wheatcroft.

"Overall, we have found the use of white light scanning to be invaluable in the sourcing of accurate, high-specification spares for our vehicles."

THIRD ABERLINK CMM

Wall Colmonoy, near Swansea, has installed an Aberlink Axion Zenith Too co-ordinate measuring machine (01453 884461). A manufacturer of wear protecting and joining solutions, the company undertakes heat treatment, brazing and machining. The Zenith Too is the third Aberlink CMM to be installed.

David Wilmer, WCL's inspection supervisor, explains: "After seriously considering the alternatives, we purchased our first Axiom CMM from Aberlink more than 15 years ago. The accuracy and ease of use of our first Aberlink machine, together with its ability to operate within our harsh environment, meant that, soon after the launch of the successor to our first CMM, we obtained the enhanced Axiom Too machine. Now based within our machine shop, the Axiom Too's user friendly characteristics allow our machine operators to make regular in-process checks and to measure first-off components.

"Our recent purchase, the much larger Aberlink Zenith Too, is situated in our environmentally controlled Inspection department where it is used to accurately measure both single large components, and, because of its generous bed size and fully automated, CNC capability, multiple, jig-mounted smaller parts. "

Image: The Aberlink Zenith Too is Wall Colmonoy's third

The Zenith CMM range encompasses 10 machines, with X,Y,Z specifications from 1,000 by 1,000 by 600 mm to 1,000 by 3,000 by 800 mm.

"Having explored the alternatives, we felt at the time of our first CMM purchase that Aberlink had a definite edge over the opposition. Although we are aware of the developments made by other CMM manufacturers in the intervening years, we remain convinced that the technical progress made by Aberlink over the last 15 years makes their CMMs by far the most suitable for our particular purposes."