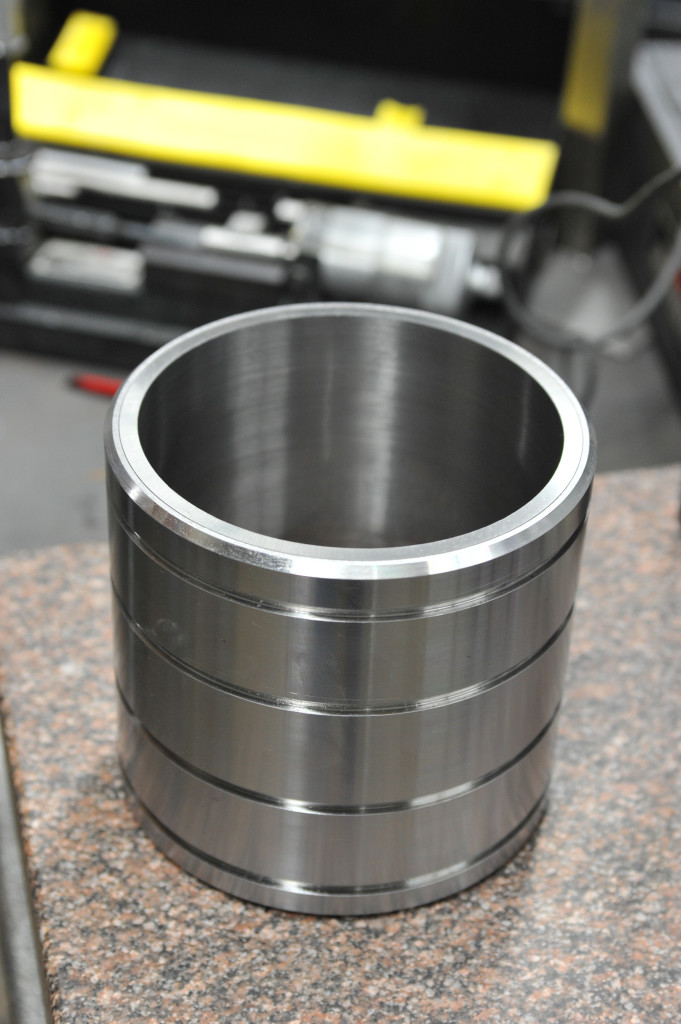

Increasing a shop’s machining capabilities is often one of the shortest routes to increasing business, as exotic materials specialist Damen Carbide Tool Co., Inc. (Wood Dale, IL) recently proved with the addition of a powerful, 60 in (1524 mm) stroke honing system that finishes holes up to 9 in (228.6 mm) diameter.

The pairing of the SV-560’s 20 hp (15 kW) spindle and 10 hp (7.5 kW) stroker with Sunnen superabrasives delivers high stock removal on tough materials, such as carbide.

The SV-560 features an intuitive interface and advanced Windows-based PC control to simplify the honing process and allow anyone withmult-axis experience to run the machine like an expert.

The Sunnen SV-560 hone allows the manufacturer of tooling and wear parts to process larger workpieces, with better finishes, roundness and straightness for a diversified customer base in aerospace, automotive, energy, heavy equipment, defense, medical and electronics.

The pairing of the hone’s potent 20 hp (15 kW) spindle and 10 hp (7.5 kW) stroker with superabrasives delivers high stock removal on tough materials, such as the shop’s namesake carbide, as well as titanium, ceramic, stellite and other exotics.

“The new hone handles any material in our shop, and the surface finishes exceed all customer requirements,” said John Bachmeier, the president of Damen Carbide.

Tolerances on the large parts processed at Damen have gone from ±0.0005 in to ±0.0001 in. The company is meetng these requirements with the SV-‐560.

Capable of producing the 0.1μm Ra or better finishes required by Damen’s automotive and large cylinder customers, the SV-‐560’s patented, synchronized servo axes eliminate the “flattening of the crosshatch angle common with other honing machines.

The quick setup and simple operation of the CNC hone allowed Damen to easily integrate the machine into the shop’s operations and respond quickly to customers seeking high-quality finishes and tight tolerances on bushings, sleeves, valves, pump liners and other large, holed parts.

“We’ve never been shy about investing in new machine tool technology, especially when we know our customers will exploit the improved capability,” said John Bachmeier, the president of Damen Carbide. “That’s certainly been the case with the new hone and the versatility it has provided. Previously we maxed out at 8 in (200 mm) diameter and 12 in (304.8 mm) part length, and customers indicated a need to go larger. The new hone handles any material in our shop, and the surface finishes exceed all customer requirements.”

Capable of producing the 0.1 µm Ra or better finishes required by Damen’s automotive and large cylinder customers, the SV-560’s patented, synchronized servo axes eliminate the “flattening” of the crosshatch angle common with other honing machines. It produces a whole-bore, constant crosshatch, using three-axis servo control of spindle rotation, stroke and tool feed.

“Tolerances on our larger parts have gone from ±0.0005 in to ±0.0001 in,” said Bachmeier. “The only way to get these jobs done to spec is with a machine of this caliber.”

Damen uses Sunnen superabrasives with the SV-560, adding to the machine’s versatility to hone the most popular tool steels as easily as hardened steel, and handle difficult exotics like stellite, Inconel, ferrotic, Nikasil, alnico and a wide range of ceramic materials commonly cut at Damen.

Established on Damen Avenue in Chicago in 1948, Damen Carbide Tool Co. Inc. started as a grinding shop making carbide saws, knives and accessory parts. The company was purchased by Bachmeier’s father in 1955 and has been the family business ever since.

In the early years of the shop, 90 percent of Damen’s customers were Chicago-area manufacturers needing carbide cutting parts. Now parts suppliers from all over the world look to Damen to provide high-quality carbide, ceramic, titanium and steel alloy parts of all types, especially those with a hole.

The SV-560’s powerful 60 in (1524 mm) stroke finishes holes up to 9 in (228.6 mm) diameter.

The Sunnen SV-‐560 allows Damen Carbide to process larger workpieces, with better finishes, roundness and straightness.

The company has more than 100 machine tools performing milling, turning and EDM machining in addition to flat, ID, OD and profile grinding. The shop added honing to its operation in the early 1960s, and still runs two older model Sunnen hones – an EC-3500 and MBC-1801 – as well as a SV-210 CNC vertical hone purchased in 2007.

“We’ve always purchased top-of-the-line machines, and when it comes to honing equipment, we have proven to ourselves that these machines are built to last and can handle anything we throw at them,” said Bachmeier.

“Customer feedback across the board showed a need for high-quality finishes, better roundness and better straightness on large parts such as mud pump liners,” noted Bachmeier. “The SV-560 allows us to meet all these requirements.”

Automatic geometry correction and auto-dwell capabilities provide excellent bore straightness, and handle blind bores with ease. The SV-560’s electromechanical design also provides servo-accurate performance and eliminates the drift inherent to hydraulic machines.

“This is a very easy machine to operate,” said Bachmeier. “Once we get the specs dialed in we tell the operators, just load and unload the parts and don’t touch anything else.”

The shop also recently acquired four Sunnen dial bore gages to measure for the bore variation of finished parts.

The quick setup and simple operation of the SV-‐560 CNC hone allowed Damen Carbide to easily integrate the machine into the shop’s operations.

According to Bachmeier, major factors when acquiring new equipment are the quality of the parts the machine turns out and its versatility.

“The ability to take care of our customers quickly and provide high-quality parts to spec is key to our business success,” he stressed. “Turnaround times are getting shorter and shorter, and sometimes the ability to deliver on time is the difference between getting a job or not. So, we need our equipment to be versatile, reliable and easy to set up.”

The SV-560 features an intuitive interface and advanced Windows®-based PC control to simplify the honing process and allow anyone with multi-axis experience to run the machine like an expert.

Even with the increased size capability – and business – that Damen garnered from acquiring the new hone, the shop still budgeted room for future growth.

“Right now we’re honing 4 in to 9 in (101.6 mm to 228.6 mm) diameter holes on parts 15 in to 30 in (381 mm to 762 mm) long,” added Bachmeier. “So, with the 60 in stroke, we can handle even larger parts, before we have to look at one of those huge tube hones.” sales@sunnen.com, www.sunnen.com