It may be easy to mill aluminum fast when the finished specs are in the standard 32 to 63 RMS range, but when you’re after single-digit finishes things can get dicey. Slowing down doesn’t necessarily help. Often the only apparent remedy is to change inserts frequently, which runs up tooling costs and slows down everything.

It may be easy to mill aluminum fast when the finished specs are in the standard 32 to 63 RMS range, but when you’re after single-digit finishes things can get dicey. Slowing down doesn’t necessarily help. Often the only apparent remedy is to change inserts frequently, which runs up tooling costs and slows down everything.

That’s the bad news. There is good news however from a couple shops that report they have doubled the machining rate on critical aluminum workpieces following a simple retooling, while holding single-digit finish specs, and without having to index every 5-10 minutes.

In Baltimore, Excel Machining and Fabrication Inc. is milling grooves in a 6061 aluminum cover for an airborne contamination detector at 105 IPM, yet the operators are able to hold 4-6 RMS so consistently that they’ve done away with 100% inspection. And, the shop’s tool life is up by ten to one.

In Grant Park, Ill., R&R Racing Products has halved cycle time to mill auto-racing connecting rods from proprietary aluminum billets, while keeping surface finish within 9 RMS. An operation that used to take 55 minutes is done now in 28 minutes.

The tool that made the most difference for these shops is the new Aluminator milling cutter from Ingersoll Cutting Tools. It employs a precision-machined insert pocket coupled with inserts that feature a polished rake face, up-sharp ground cutting edges, and integral wiping flats with a larger radius blend that work together to allow faster feedrates. These four features work together to enable faster metal removal with lower cutting forces and finer finishes. “The ground-and-polished insert and precision locating surface used to mount the insert onto the cutter body is what delivers fine finishes,” according to Mark Teno, Ingersoll’s engineering manager for aerospace products design. “The other critical features help to keep that edge sharper longer by fostering a cleaving-type cutting action, distributing the cutting forces over a larger area and directing them axially rather than laterally.”

No wiggle room at Excel

Excel had to find a better milling process to meet delivery schedules, and to comply with a finish standard that specifically forbade hand finishing. “We had no choice but to impart the required finish as part of the milling,” recalled milling foreman Jeff Grueninger.

The workpiece in question is a 6061 aluminum housing for airborne anthrax detectors, which measure about the size of a paperback book.

Grueninger’s principal machining problem was to achieve an 8 RMS finish and a 0.0005-in. flatness in a very difficult gasket channel — as-machined, without taking all day. The customer needed 125 complete housings each week, leaving no time for hand-work even if the specs had allowed it.

Grueninger’s principal machining problem was to achieve an 8 RMS finish and a 0.0005-in. flatness in a very difficult gasket channel — as-machined, without taking all day. The customer needed 125 complete housings each week, leaving no time for hand-work even if the specs had allowed it.

First, Excel tried a two-inch wiper-type facemill with four inserts of three different styles, but even at 42 IPM feed or less, surface-finish ranged from 7 to 35 RMS. So, every piece needed a Profilometer check, too often followed by reworking. Moreover, insert edges lasted less than 100 pieces, with indexing taking more than half an hour each time.

“With three different inserts to juggle, it took a rocket scientist to index the thing,” said Grueninger. “It was a real bottleneck.”

He also tried another cutter with triangular inserts, but without any improvement. In fact, cutting loads ran up to 120 percent of spindle capacity.

Trying something new

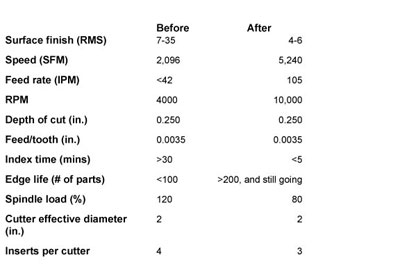

Ingersoll field engineer Randy Bohn suggested a new facemill for aluminum called the Aluminator, and set up a test on Excel’s Kitamura CNC machine, following modern high-feed milling practices. The new cutter consistently delivered surface finishes in the range of RMS 4, and at much higher cutting rates. The following table summarizes the results, before and after Excel Machining and Fabrication adopted the Aluminator cutters:

Tests vs. the real world

To test the new cutter’s limits, Randy Bohn ran some test parts at 265 IPM. Even under those conditions, surface-finish still remained well within spec, spindle load remained within limits, and the insert edges stood up just fine.

Nevertheless Jeff Grueninger started at the more conservative rate shown in the table above. Even so, he was more than doubling throughput. “We can take risks in a one-time test that we can’t in day-to-day shop practice.” says Grueninger. “We’ll ramp up the machining rate, but gradually.”

After several months, surface-finish has remained so consistently within limits that Excel dispensed with 100% inspection, saving a few additional dollars in its total costs of production.

After several months, surface-finish has remained so consistently within limits that Excel dispensed with 100% inspection, saving a few additional dollars in its total costs of production.

Billets on the starting line at R&R

While most con-rod producers start with forged workpieces, R&R starts with solid billets (for end-use strength) and then removes 75% of the metal to reach net shape. The billets are made of a proprietary aluminum with 25% better mechanical properties than standard alloys. “We’ve dubbed it ‘unobtanium,’” co-owner Julie Riechers boasted. “It’s somewhat like 7075 aircraft alloy in mechanical properties and a typical T-6 in machinability.”

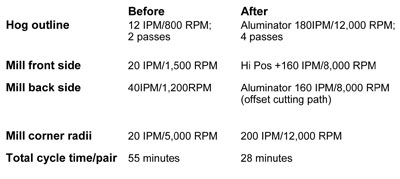

From 1992 until last summer, R&R machined the aluminum rods two-up in four basic steps:

1.Mill the outline in two passes with a three-flute high speed steel roughing end mill;

2.Mill the front side with a 4 in., 8-flute facemill;

3.Mill the back side with the same mill;

4.Round off the edges with a carbide wood router.

A little help from friends

Then, last June, Mike Riechers moved up to high-speed machining (HSM), adding a light-duty CNC vertical with a 12,000-RPM spindle. Soon, a decision was needed to determine how best to tool it, and he turned to Ingersoll’s Konrad Forman for an answer.

In all cases Forman advocated the modern high-feed practice (much higher feed rates and shallower cuts) which removes metal faster without overloading a light-duty HSM machine. As to tooling, Forman recommended the HSM-rated Ingersoll Aluminator, in two different diameters, for the first and third operations. For the second, he replaced the old, corncob cutter with a 1.5-inch Hi Pos+ facemill. For edge-rounding, the final step, he recommended an Ingersoll Fast-Break rounding tool.

In the end, cycle times for each operation were cut by about 50%, leading up to a production time reduction from 55 to 28 minutes, all told. Here’s the breakdown:

“Besides running faster, the new process runs smoother, and actually improves the surface finish,” Mike Riechers reported. “I’m sure we’re protecting both machine and tooling, as tool life has improved greatly. But mainly, the smoother finish reduces still more potential stress factors – on components that are certain to see a lot of stress.”

Helical cutter eases in

Helical cutter eases in

Used for the backside of the con rods, the Hi Pos+ cutter combines double-positive geometry with a helical cutting edge, which induces a cleaving type cutting action. “Their curved edge eases the insert into the workpiece, reducing cutting impact forces by 40%,” explained Forman. “On the micro level, it’s much like the way that an angled blade on a sheet-metal shear cuts just a portion at a time rather than slamming into the sheet all at once. This permits very high feedrates while keeping cutting forces — especially impact forces — within limits. It also directs more of the cutting forces axially, up the spindle, rather than laterally, to further protect the sometimes-fragile HSM spindles.”