| allmetalworking > Product News Content > Micro Roller Burnishing Tools allow the effective length of the tool to be kept compact |

|

|

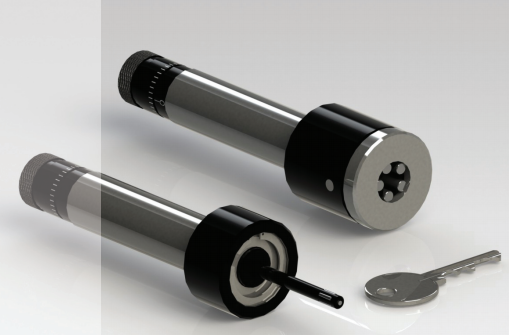

| Micro Roller Burnishing Tools allow the effective length of the tool to be kept compact |

Cogsdill Tool Products, Inc. is pleased to announce the addition of our new Micro Roller Burnishing Tools to our family of Burnishing products. The Micro Roller Burnishing Tool program offers a compact design for use where limited space is available on multi-spindle automatic and screw type machines. This new program offers a unique rear adjustment mechanism which allows the effective length of the tool to be kept compact.

The new program is offered in both internal and external styles. Internal thru style tools are offered in sizes from 0.187-0.501 inch (4.75-12.73mm) diameter, and bottoming style for diameters larger than 0.246 inch (6.25mm). External tools are offered in sizes from 0.054-0.254 inch (1.37-6.45mm) diameter in bottoming style.

Refer to our new Micro Roller Burnishing Tools brochure #501 for our product program, assembly and disassembly instructions, and tool adjustment instructions. View our new catalog online at www.cogsdill.com. For additional information, contact our Customer Service Department, one of our Regional Sales Managers or Manufacturer’s Representatives, or one of our distributors located in your area. |

| Tags: |

| |

| About this company: |

Cogsdill-Nuneaton, Ltd., designs and manufactures specialty

tooling for the metal machining industries:

1)Roller burnishing tools and machines (and diamond burnishing

tools), for sizing, finishing, and work-hardening in seconds

2)Hole deburring tools and back-spotfacing tools, for edge break

and burr removal on both sides of drilled holes in one pass

Shefcut precision reamers and precision boring tools, for accurate

size, fine finish, and superior hole geometry

3)Automatic recessing tools and generating heads, for fast,

accurate, and repeatable grooving, recessing, facing, and

chamfering operations

4)ZX Systems, for boring, facing, and contouring operations in one

set-up

Perform difficult machining tasks, and eliminate multiple set-ups

and secondary operations. Produce better quality parts, with

faster and more economical production. Standard, off-the-shelf

tooling; custom tool design; applications engineering assistance;

and worldwide service and support. |

| Company Information: |

| Company Name: |

Cogsdill - Nuneaton Ltd. |

| Address: |

Tenlons Road |

| City: |

Nuneaton |

| State/Province: |

|

| ZIP: |

CV10 7HR |

| Country: |

United Kingdom |

| Phone Number: |

+44-24-76383792 |

| FAX: |

+44-24-76344433 |

|

|

|

| |

| Note: The copyright and the ownship of the brand, product names, product numbers, and content mentioned belongs to their repective companies. |

| |

|