The highest level of quality

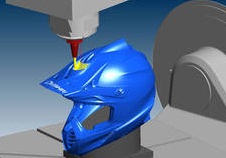

In order to apply hyperMILL®‘s excellent toolpaths reliably to the machine while avoiding any disruption during use, OPEN MIND Technologies AG produces all of its postprocessors itself for its customers. These postprocessors are therefore an integral component of a high-quality CAM postprocessor solution that goes far beyond generalised standard solutions in terms of performance and safety.

Development in the machine tool sector is proceeding rapidly. In the meantime, several milling machines can also perform turning operations, and the milling capabilities of turning machines are being enhanced every year.

Complete machining of workpieces is commonplace among users – turning, drilling and milling – 2.5D, 3D, 5axis.

OPEN MIND Technologies AG has accompanied this development in the machine sector from the beginning, so they understand how the postprocessor, as the interface to tool machines, is an integral component of their high-quality CAM package.

OPEN MIND produces nearly 100 percent of all of their postprocessors for this very reason. This successfully combines two crucial points in this service: specific customer requirements and performance, including the absolutely necessary factor of safety!

Every user has specific ideas about the NC programming format based on their respective company’s parts portfolio and their experience. OPEN MIND strives to make these ideas a reality – without losing sight of reliable performance.

100 percent safety.

Several CAM producers simply give their customers a “generalised postprocessor”. Users are then supposed to create their own postprocessors. This approach entails a number of disadvantages. For one, it costs the customer time. Second, the result is rarely one-hundred-percent optimal in terms of the combination of machine and controller, and machining potential cannot be fully exploited.

Finally, a user doesn’t have the specialised expertise of postprocessor professionals. This comes with a certain level of risk. If there is a slight uncertainty factor in a complex 5axis program with multiple tools, this means that an additional NC verification is mandatory. This means that, after the postprocessor run, the NC program must once again be verified and edited. An additional loss of time!

OPEN MIND’s offer therefore goes far beyond the level of a generalised standard solution. “OPEN MIND always produces postprocessors that keep in mind the full functional spectrum of hyperMILL®. We are always referring to the latest expertise during this process – and the postprocessors are consistently built for the newest functions”, emphasises Torsten Köcher, head of the postprocessor department.

The broadest spectrum of applications.

Postprocessors from OPEN MIND Technologies AG are outstanding thanks in part to the way they can optimally use the functionality of each controller.

Main features at a glance:

- Control cycles – for drilling, milling and thread cutting turning

- Additional 2D functions

- Parameters, such as those for feed rate values

- NC program structures, e.g., main program and sub-routines

- Program part repetitions

- Tilted workplanes

- 5axis simultaneous machining

In order to take everything into account, OPEN MIND has 7 employees who work on postprocessors. This team has produced far more than 1,000 postprocessors since 2010 “We cover a broad spectrum of controllers, starting with worldwide leading manufacturers such as Fanuc, Siemens, Mazak Heidenhain and extending to other providers such as Okuma, Fidia, OSP”, says Torsten Köcher. OPEN MIND is striving constantly to respond to the latest controller functions with its postprocessors.

The number of tool machine manufacturers for whom postprocessors have already been developed is far larger: from A as in Alzmetall to Z as in Zayer.

So there is plenty of experience on hand, allowing OPEN MIND to always deliver the best possible postprocessors for future projects. And the best possible postprocessor is the one that users don’t even notice

|